TiB2 Titanium Diboride hmoov

Product Description

Titanium diboride yog ib qho kev sib xyaw ua ke ntawm boron thiab titanium, feem ntau hu ua TiB2.Nyob rau hauv cov nqe lus ntawm lub cev muaj zog, titanium diboride yog ib tug tawv dub khoom nrog ib tug hlau luster.Nws muaj qhov siab melting point, siab hardness, zoo hluav taws xob conductivity thiab thermal stability.Hais txog cov khoom siv tshuaj, titanium diboride yog ib qho chaw ruaj khov, insoluble hauv dej thiab alkali daws.Nws tsis hnov mob nrog dej thiab oxygen ntawm qhov kub thiab txias thiab muaj qee yam antioxidant zog.Vim tias titanium diboride muaj siab hardness, siab melting point, zoo hluav taws xob conductivity thiab kub stability thiab lwm yam zoo heev, nws yog dav siv nyob rau hauv kub kub ceramics, hluav taws xob khoom, aerospace thiab automotive teb.Raws li cov khoom siv kub kub ceramic, nws tuaj yeem siv los tsim cov khoom nrog lub zog siab thiab siab tawv.Hauv cov khoom siv hluav taws xob, titanium diboride tuaj yeem siv los tsim cov khoom siv hluav taws xob kub kub, cov khoom siv hluav taws xob ua haujlwm thiab kev sib txuas ua ke.Tsis tas li ntawd, nws tseem tuaj yeem siv rau hauv kev tsim cov hlau muaj zog thiab cov hlau alloy reinforcement cov neeg ua haujlwm thiab cov txheej txheem saum npoo.

Cov lus qhia tshwj xeeb

| TiB 2 | 99% |

| Ti | 68% |

| B | 30% |

| Fe | 0.10% |

| Al | 0.05% |

| Si | 0.05% |

| C | 0.15% |

| N | 0.05% |

| O | 0.50% |

| Lwm yam | 0.80% |

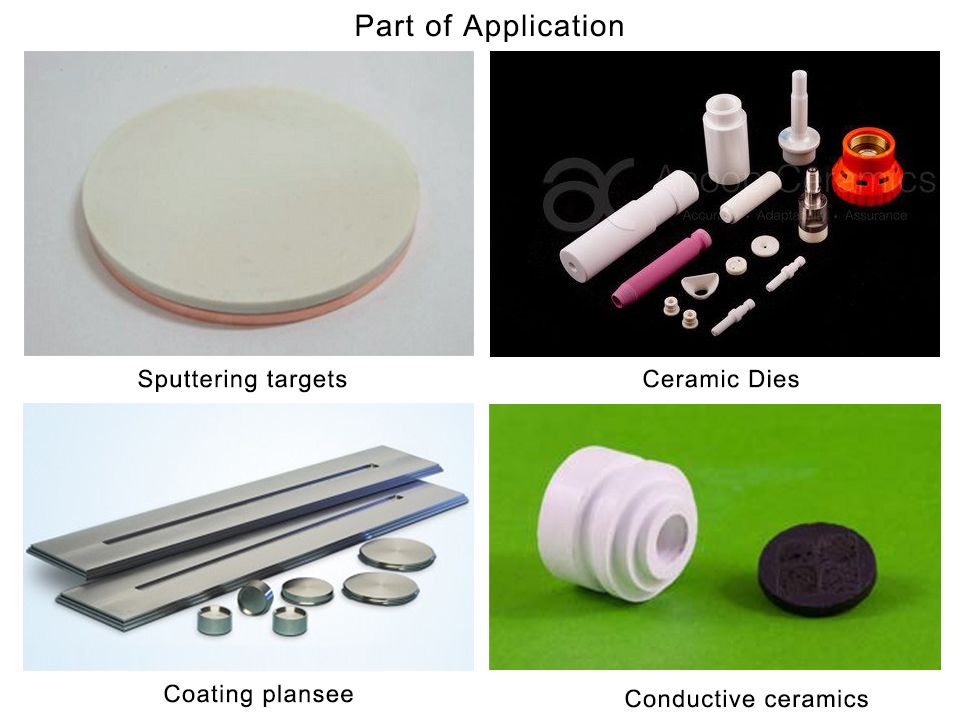

Daim ntawv thov

1. Cov khoom siv ceramic

Nws yog ib qho ntawm cov khoom siv tseem ceeb ntawm lub tshuab nqus tsev vacuum conductive evaporation nkoj.

2. Ceramic tej cuab yeej thiab tuag

Nws tuaj yeem siv los tsim cov cuab yeej ua tiav, xaim kos duab tuag, extrusion tuag, sandblasting nozzles, sealing Cheebtsam thiab lwm yam.

3. Composite ceramic khoom

Nws tuaj yeem siv los ua ib qho tseem ceeb ntawm cov khoom siv sib xyaw ua ke los tsim cov ntaub ntawv sib xyaw nrog TiC, TiN, SiC thiab lwm yam ntaub ntawv los ua ntau yam kub-resistant qhov chaw thiab qhov chaw ua haujlwm, xws li kub kub crucibles, cav qhov chaw, thiab lwm yam. . Nws kuj yog ib qho ntawm cov ntaub ntawv zoo tshaj plaws los ua cov khoom siv tiv thaiv armor.

4. Cathode txheej khoom siv rau txhuas electrolytic cell

Vim tias qhov zoo wettability ntawm TiB2 thiab kua txhuas hlau, TiB2 raws li cov khoom siv cathode txheej ntawm txhuas electrolyzer tuaj yeem txo lub zog noj thiab ua kom lub neej ntev ntawm txhuas electrolyzer.

5. PTC cua sov cov ntaub ntawv ceramic thiab hloov tau PTC cov ntaub ntawv

Nws muaj cov yam ntxwv ntawm kev nyab xeeb, txuag hluav taws xob, kev cia siab, kev ua haujlwm yooj yim thiab molding, thiab lwm yam. Nws yog ib qho khoom siv high-tech tshiab ntawm ntau yam khoom siv hluav taws xob cua sov.

6. Tus neeg saib xyuas zoo rau cov khoom siv hlau xws li Al, Fe, thiab Cu.