plasma spray cobalt alloy hmoov

Product Description

Cov khoom zoo heev ntawm cobalt-based alloy hmoov yog vim nws cov tshuaj lom neeg tshwj xeeb thiab microstructure.Nws yog tsim los ntawm ntau yam hlau ntsiab lus sib xyaw ua ke raws li ib qho kev faib ua feem tom qab kub melting, uas cov ntsiab lus ntawm cobalt yog siab dua, yog li nws muaj zoo hardness thiab corrosion kuj.Nyob rau tib lub sijhawm, cov hlau tseem muaj qhov tsim nyog ntawm cov hlau, chromium thiab lwm yam khoom, kom nws muaj kev hnav zoo dua.Hauv kev tsim cov txheej txheem, cobalt-based alloy hmoov yog tsim los siv cov txheej txheem hmoov metallurgy siab heev.Ua ntej, cov ntsiab lus hlau yog tov raws li ib qho kev faib ua feem, thiab tom qab ntawd los ntawm kev kub siab melting, ceev ceev txias thiab lwm yam txheej txheem, thiab thaum kawg tau txais ib tug zoo, uniform alloy hmoov.Cov hmoov no muaj cov qib siab ntawm fluidity, txhaws thiab sintering zog, thiab tuaj yeem ua tiav rau hauv ntau yam duab ntawm qhov chaw.

Specification

| Yam khoom | HR-Co1 | HR-CO 6 | HR-Co12 | HR-CO 21 |

| HRC | 48 | 38 | 42 | 28 |

| C | 2.4 | 1.15 | 1.4 | 0.25 |

| Cr | 30.5 ib | 29 | 29.5 Nws | 27.5 ib |

| Si | 1 | 1.1 | 1.45 Nws | 2 |

| W | 12.5 Nws | 4 | 8.25 Nws | 0.15 |

| Fe | 3 | 3 | 3 | 2 |

| Mo | 1 | 1 | 1 | 5.5 |

| Ni | 3 | 3 | 3 | 2.5 |

| Co | Bal | Bal | Bal | Bal |

| Mn | 0.25 | 0.5 | 1 | 1 |

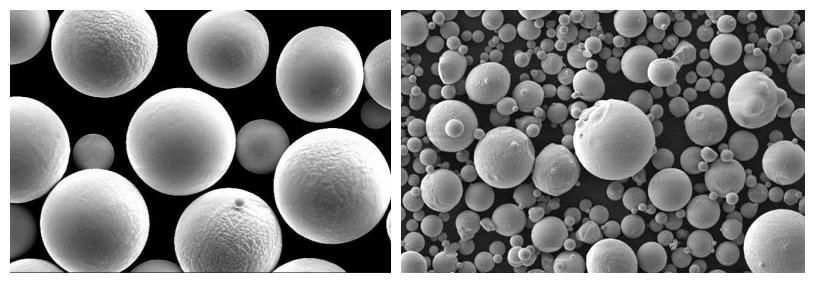

Sem

Cov ntawv thov tseem ceeb

Cobalt-based alloys muaj lub zog siab, ua haujlwm zoo rau thermal qaug zog, thermal corrosion thiab puas, thiab zoo weldability ntawm qhov kub siab tshaj 980 ℃.Haum rau aviation dav hlau cav, muaj roj turbine, nkoj roj turbine qhia vane thiab nozzle qhia vane thiab diesel nozzle thiab lwm yam.

1. Kev nyuaj siab

2. Wear-resistant Welding TIG/MIG

3.Thermal spray PTA/HVOF

HUARUI cobalt alloy hmoov kom zoo dua

● siab sphericity

● Cov tshuaj lom neeg muaj pes tsawg leeg homogeneity

● siab pom tseeb / tapping ceev

● Cov ntsiab lus suav nrog tsawg

● Cov pa oxygen tsawg

● High flowability

● Uniform nto thickness thiab tsawg porosity