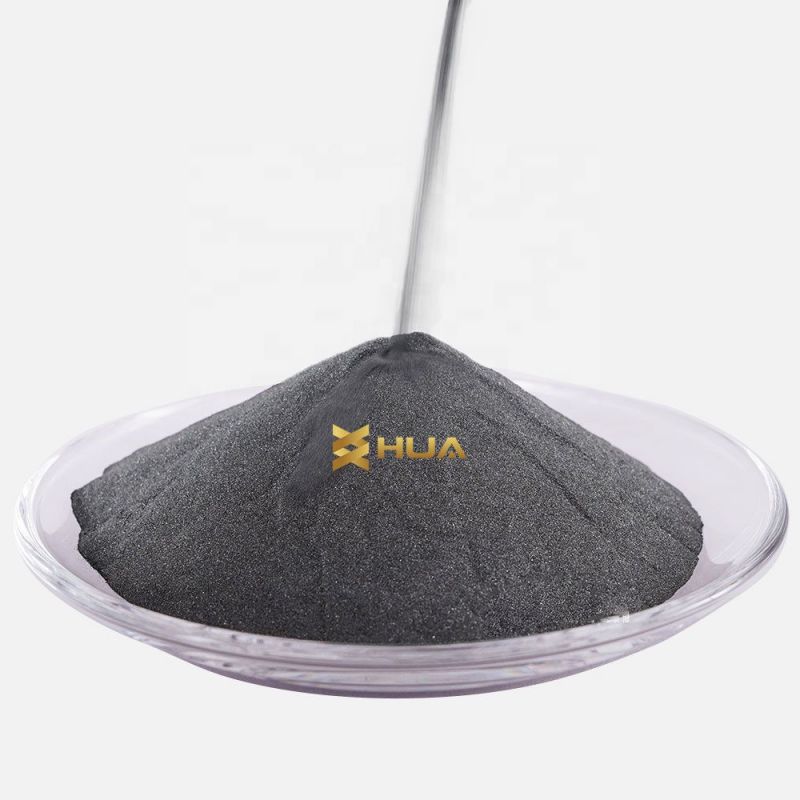

Hlau alloy titanium hmoov ti6al4v hmoov rau 3d luam ntawv

Product Description

Ti6Al4V hmoov hu ua TC4, yog α-β titanium alloy nrog lub zog-rau-hnyav piv thiab zoo heev corrosion kuj.Nws yog ib qho ntawm feem ntau siv titanium alloys thiab yog dav siv nyob rau hauv tsawg ntom thiab zoo heev corrosion kuj yog tsim nyog rau xws li aerospace kev lag luam thiab biomechanical daim ntaub ntawv ( cog thiab prostheses ).Ti6Al4V feem ntau suav hais tias yog "puag" ntawm titanium kev lag luam. vim hais tias nws yog nyob deb ntawm cov feem ntau siv titanium alloy, ntau tshaj 50% ntawm tag nrho cov nyiaj ntawm titanium.

TC4 titanium alloy muaj zoo heev corrosion kuj.Nws muaj cov txiaj ntsig zoo xws li qhov tsis tshua muaj siab, siab tshwj xeeb lub zog, zoo toughness, zoo weldability thiab lwm yam.Nws tau siv dav hauv aerospace, petrochemical, nkoj tsim, tsheb, tshuaj thiab lwm yam lag luam.

Cov lus qhia tshwj xeeb

| Titanium nitride hmoov muaj pes tsawg leeg | |||

| Yam khoom | TSI-1 | TSI-2 | TSI-3 |

| Purity | > 99.0 | > 99.5 | > 99.9 |

| N | 20.5 ib | > 21.5 | 17.5 Nws |

| C | <0.1 | <0.1 | 0.09 ib |

| O | <0.8 | <0.5 | 0.3 |

| Fe | 0.35 Nws | <0.2 | 0.25 |

| Qhov ntom | 5.4g / cm3 | 5.4g / cm3 | 5.4g / cm3 |

| qhov loj | <1 micron 1-3 micron | ||

| 3-5 micron 45 micron | |||

| thermal expansion | (10-6K-1): 9.4 tsaus / daj hmoov | ||

Specification

| Titanium aluminium alloy (TC4) hmoov Khoom | |||||

| Qhov Loj | 0-25 hli | 0-45 hli | 15-45 Nws | 45-105 : kuv | 75-180 Nws |

| Morphology | kheej kheej | kheej kheej | kheej kheej | kheej kheej | kheej kheej |

| PSD-D10 | 7 awm | 15 awm | 20 awm | 5 3 awm | 8 0 awm |

| PSD-D50 | 15 awm | 3 4 awm | 3 5 awm | 7 2 awm | 125 ua |

| PSD-D90 | 24 awm | 48 awm | 50 awm | 105 ua | 200 ua |

| Flow peev | N/A | ≤120S | ≤ 50S | ≤ 25S | 23 S |

| Pom Ntsig | 2.10g / cm3 | 2.55g / cm3 | 2.53g / cm3 | 2.56g / cm3 | 2.80g / cm3 |

| Cov ntsiab lus Oxygen (wt%) | O: 0.07-0.11wt%, ASTM tus qauv: ≤0.13wt% | ||||

Peb kuj muab kev pabcuam customized

Txais tos kom yuav tsum tau COA & qauv dawb rau Kev Xeem

SEM

| Titanium aluminium alloy (TC4) hmoov Cov ntsiab lus tseem ceeb: | ||

| Al | V | Ti |

| 5.50-6.75 Nws | 3.50-4.50 Nws | Bal |

Daim ntawv thov

1. laser / electron beam ntxiv manufacturing (SLM / EBM).

2. hmoov metallurgy (PM) thiab lwm yam txheej txheem.

3. ntau hom 3D hlau luam ntawv, suav nrog Renishaw, Renishaw, Lub teb chaws Yelemees EOS (EOSINT M series), Lub tswv yim Laser, 3D tshuab thiab lwm yam khoom siv laser melting.

4. kev tsim khoom ntawm aerospace qhov chaw, Aeroengine Blades thiab lwm qhov chaw ntawm kev kho cov haujlwm.

5. khoom siv kho mob.