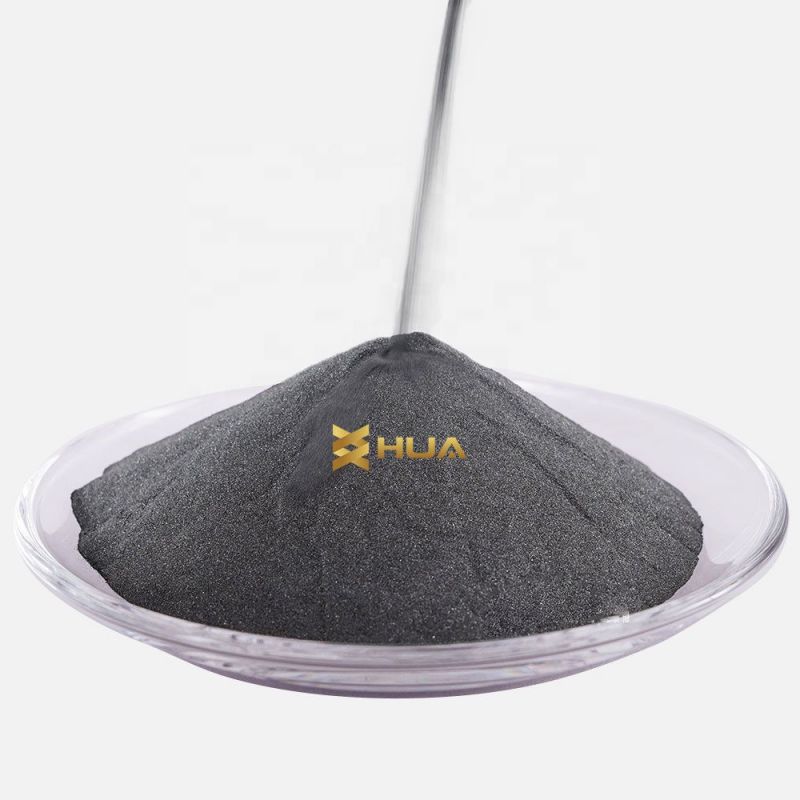

Hlau raws alloy hmoov rau thermal spray hmoov

Product Description

Hlau raws alloy hmoov yog hais txog cov hmoov hlau alloy nrog hlau hlau ua cov khoom tseem ceeb.Nws tuaj yeem siv tau thiab kawm tau zoo hauv cov khoom siv hlau, thermal txau teb thiab cov txheej txheem hmoov metallurgy.Cov hlau raws alloy hmoov peb muab muaj cov yam ntxwv ntawm siab purity, uniform particle loj thiab zoo sphericity.Yuav siv tau los tsim cov hmoov metallurgy machinery qhov chaw.Haum rau cov hmoov hlau metallurgy qhov chaw, dav siv hauv tsheb, maus taus, khoom siv hauv tsev, cov cuab yeej hluav taws xob, tshuab ua haujlwm, tshuab ua liaj ua teb, tshuab cuab yeej, instrumentation, textile machinery, metallurgical machinery thiab lwm yam.

Specification

| Atomized Hlau Raws li Alloy Hmoov | |||||

| Qib | Chemistry | Flow Density | Loj | Hardness | Daim ntawv thov |

| FeNiCrSiB Fe30 | C 0.2 | 20-25s / 50g3.8g / cm3 | -150 + 45 hli -106+45 : kuv | 30 HRC | sWith favourable antifaingue propetly, muaj feem xyuam rau qhov tshwm sim nyob rau hauv rov qab cuam tshuam tab sis nrog tsawg hardness yuav tsum tau |

| FeNiCrSiWB Fe45 | C 0.6 | 20-25s / 50g 3.8g / cm3 | -150 + 45 hli -106+45 : kuv | 45 HRC | sKev kho lub ntsej muag sealing ntawm lub valve thiab qhov chaw tsis zoo ntawm lub tshuab |

| FeNiCrSiB Fe55 | C 1.2 | 20-25s / 50g 3.8g / cm3g | -150 + 45 hli -106+45 : kuv | 55 HRC | s Rau kev kho ntawm harrow daim duav hniav, roj av drilling pas nrig sib koom tes thiab scraper ncej |

| FeNiCrSiB Fe60 | C 1.5 Si 3.5 IB 3.0 Cr 35 Nws 15 Fe Bal | 20-25s / 50g 3.8g / cm3g | -150 + 45 hli -106+45 : kuv | 60 HRC | s Rau kev kho ntawm harrow daim duav hniav, roj av drilling pas nrig sib koom tes thiab scraper ncej |

| FeNiCrSiB Fe55T | C 0.8 Si 2.0 IB 1.5 Cr 14 Nim 6 Fe Bal | 20-25s / 50g 3.8g / cm3g | -150 + 45 hli -106+45 : kuv | 55 HRC | s Rau kev kho ntawm harrow daim duav hniav, roj av drilling pas nrig sib koom tes thiab scraper ncej |

Kev tswj hwm qhov system

Huarui muaj kev tswj xyuas zoo.Peb sim peb cov khoom ua ntej tom qab peb ua tiav peb cov khoom, thiab peb sim dua ua ntej txhua qhov khoom xa tuaj, txawm tias cov qauv.Thiab yog tias koj xav tau, peb xav lees txais cov neeg thib peb los kuaj.Tau kawg yog tias koj nyiam, peb tuaj yeem muab cov qauv rau koj los kuaj.

Peb cov khoom zoo yog lav los ntawm Sichuan Metallurgical Institute thiab Guangzhou lub koom haum ntawm Kev Tshawb Fawb Hlau.Kev koom tes ntev nrog lawv tuaj yeem txuag tau ntau lub sijhawm sim rau cov neeg siv khoom.