Cobalt Base Alloy vuam Rods stellite rode prezzo

Product Description

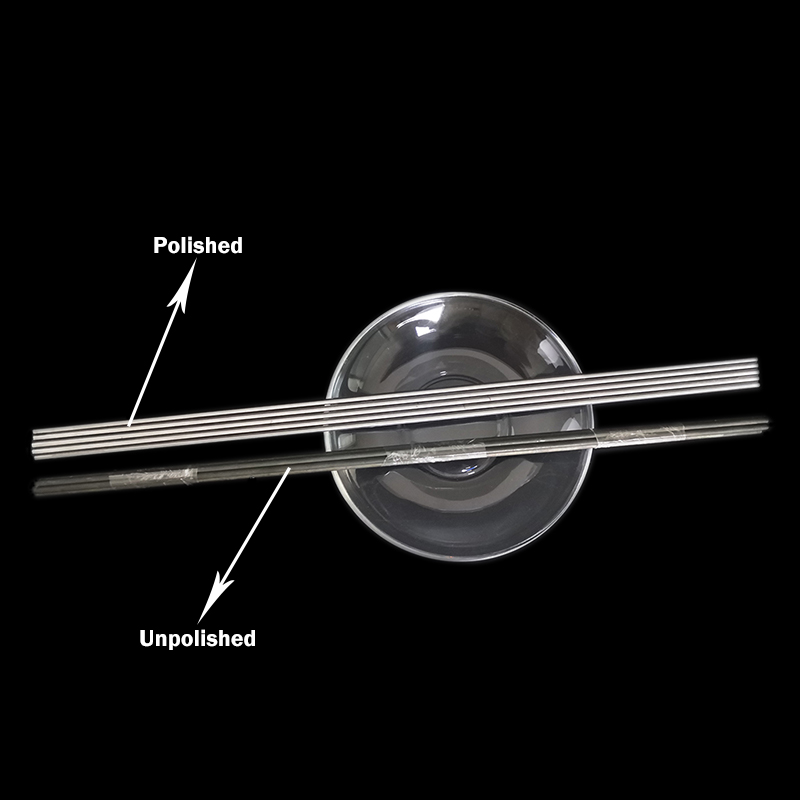

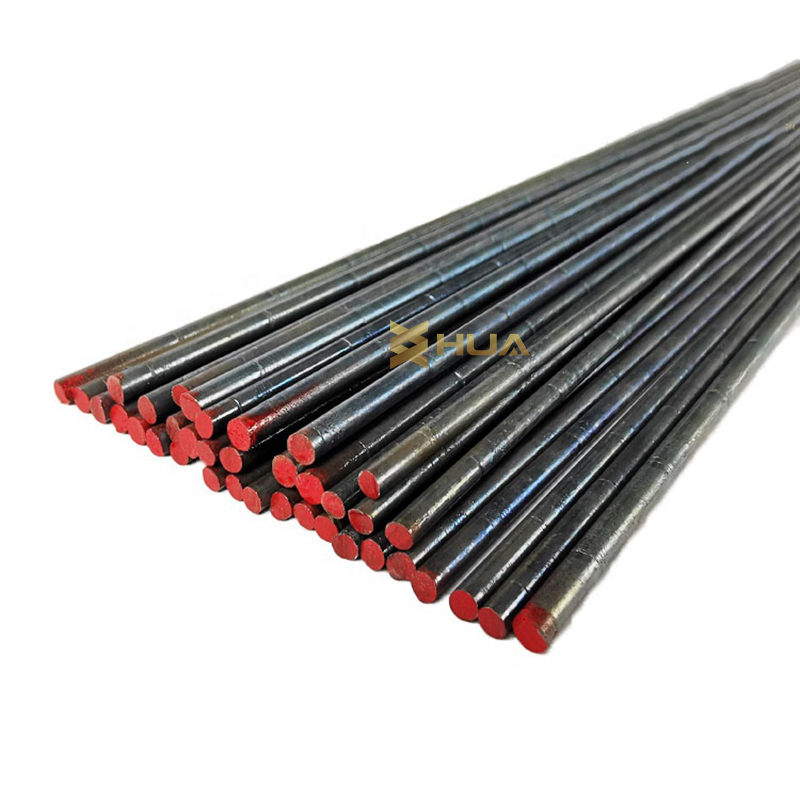

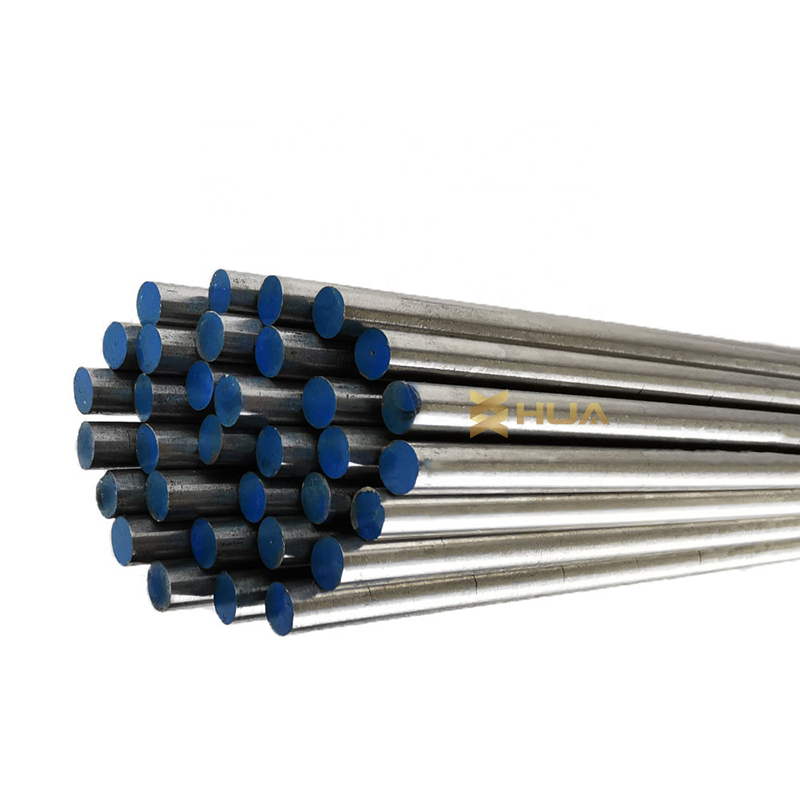

Tig Welding Co 1 6 Bar Cobalt Base Alloy Bare Rods

Cobalt-Based Alloy Bare Qws:

- AWS RCoCr-C (HR CO1)

- AWS RCoCr-A (HR CO6)

- AWS RCoCr-B (HR CO12)

AWS RCoCr-C (1#)

Nws muaj kev hnav zoo heev thiab kub ua haujlwm ntawm qhov kub thiab txias.

Pom zoo siv los ua valve seal inserts, rotating sealing nplhaib, laum taub hau, cutter ntug, thiab lwm yam

AWS RCoCr-A (6#)

Feem ntau siv Cobalt Alloy nrog cov khoom siv zoo ntawm qhov sib txawv ntawm qhov kub thiab txias, Pom zoo siv los ua cov khoom siv lub rooj zaum, kub shear hniav, kub kub valve, turbine hniav, thiab lwm yam.

AWS RCoCr-B (12#)

Nws muaj kev tiv thaiv zoo heev ntawm kev kub siab, corrosion thiab puas.Pom zoo siv los ua lub siab siab valve, shear ntug, sawteeth, thiab lwm yam.

AWS RCoCr-B (#21)

Nws muaj kev tiv thaiv zoo heev ntawm kev kub siab, corrosion thiab puas.Pom zoo siv los ua fuild valve, tooj dag casting tuag, vlave rooj, thiab lwm yam.

Specification

| NO | Tshuaj muaj pes tsawg leeg (%) | ||||||||

| C | Cr | Si | W | Ni | Fe | Mn | Mo | Co | |

| HR-DCO 1 | 2.1 | 30 | 1 | 14 | ≤3.0 | ≤5.0 | ≤ 2.0 | ≤1.0 | Bal |

| HR-DCO 6 | 1 | 30 | 1 | 4.6 | ≤3.0 | ≤5.0 | ≤ 2.0 | ≤1.0 | Bal |

| HR-DCo12 | 1.4 | 30 | 1 | 9 | ≤3.0 | ≤5.0 | ≤ 2.0 | ≤1.0 | Bal |

| HR-DCO21 | 0.2 | 28 | 1 | --- | ≤3.0 | ≤5.0 | ≤ 2.0 | 5.5 | Bal |

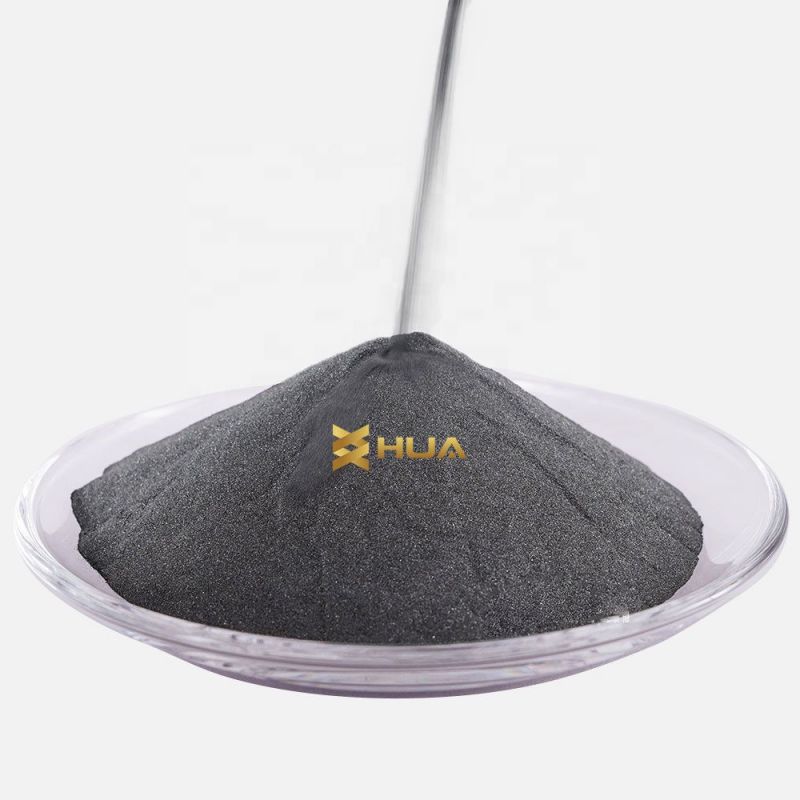

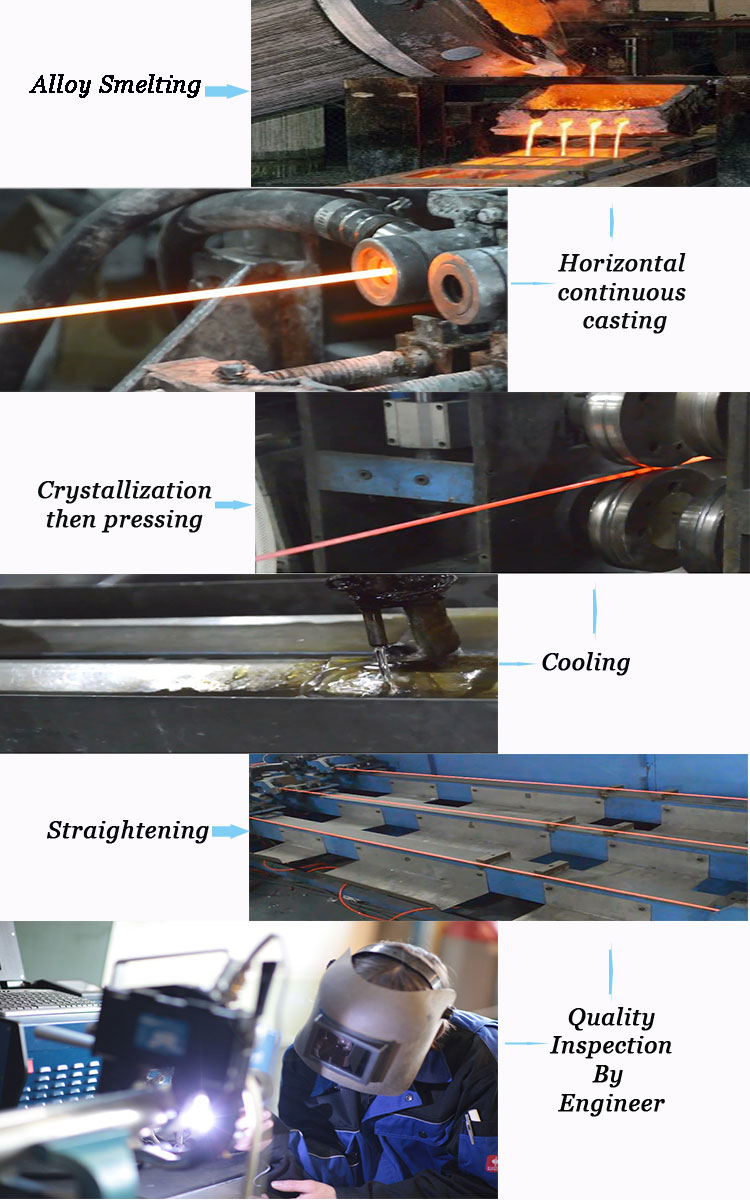

Txheej txheem ntau lawm

Daim ntawv thov

Nws yog siv rau lub sijhawm uas yuav tsum muaj kev ua tau zoo nyob rau hauv cov xwm txheej ntawm hnav thiab corrosion kuj ntawm qhov kub thiab txias.Xws li tsheb, sab hauv combustion engine li qub, siab kub thiab siab siab li qub, kub shear hniav, sab hauv thiab sab rings ntawm bearings, kub forging tuag, thiab lwm yam.