spherical alumina hmoov

Product Description

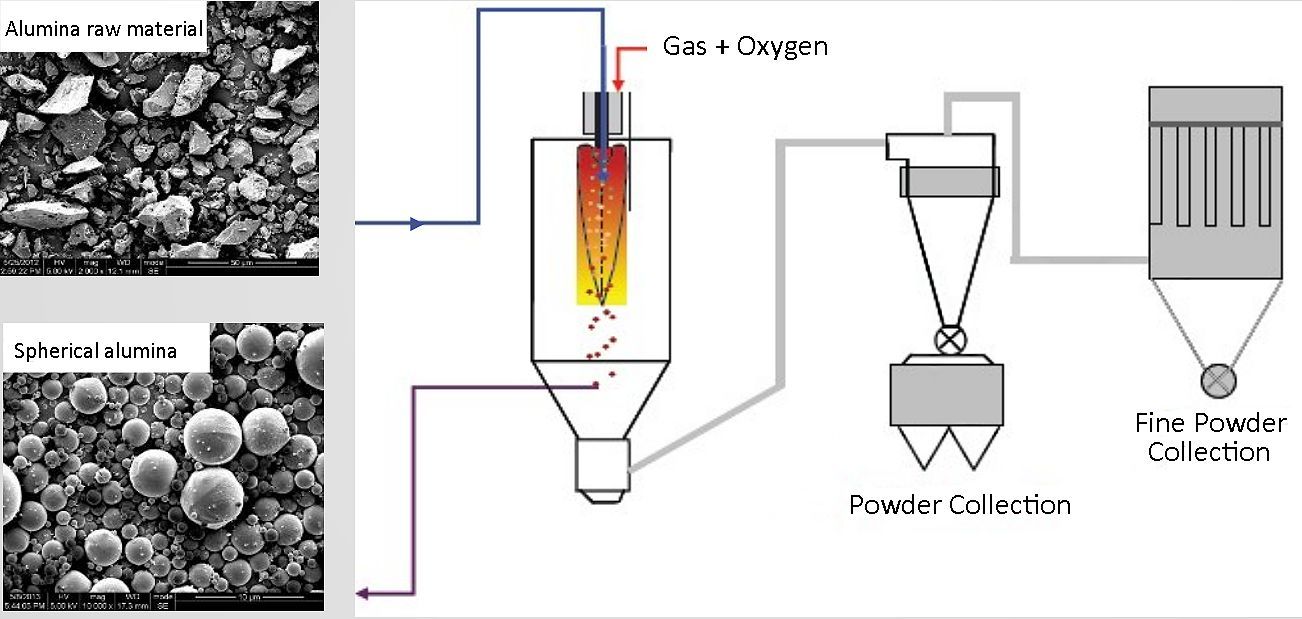

Spherical alumina yog cov khoom siv ua haujlwm siab nrog siab purity, spherical hais, siab hardness, siab hnav tsis kam, siab corrosion kuj, siab thermal stability thiab zoo hluav taws xob rwb thaiv tsev.Spherical alumina muaj siab hardness thiab lub zog, uas ua rau nws zoo tagnrho hnav-resistant khoom.Nyob rau hauv cov teb ntawm ceramics, electronics, tshuaj lom neeg kev lag luam thiab kev tsim kho, spherical alumina yog dav siv nyob rau hauv lub tsim ntawm advanced ceramic cov ntaub ntawv, advanced coj-resistant bearings, advanced automotive engine qhov chaw, thiab lwm yam. Spherical alumina muaj siab corrosion kuj, uas enables nws mus tswj kev ua haujlwm ruaj khov hauv ib puag ncig hnyav.Piv txwv li, nyob rau hauv Marine ib puag ncig, tshuaj lom neeg kev lag luam, kev lag luam hluav taws xob thiab lwm yam kev lag luam, spherical alumina yog siv rau hauv kev tsim cov nkoj, cov khoom siv tshuaj, khoom siv hluav taws xob thiab lwm yam.Spherical alumina muaj qhov zoo thermal stability thiab hluav taws xob rwb thaiv tsev, yog li nws muaj peev xwm tswj tau qhov kev ua tau zoo nyob rau hauv qhov kub thiab txias qhov chaw.Nyob rau hauv lub tshav pob ntawm electronics, spherical alumina yog siv nyob rau hauv lub chaw tsim khoom ntawm high-temperature electronic devices, high-voltage power equipment, etc.

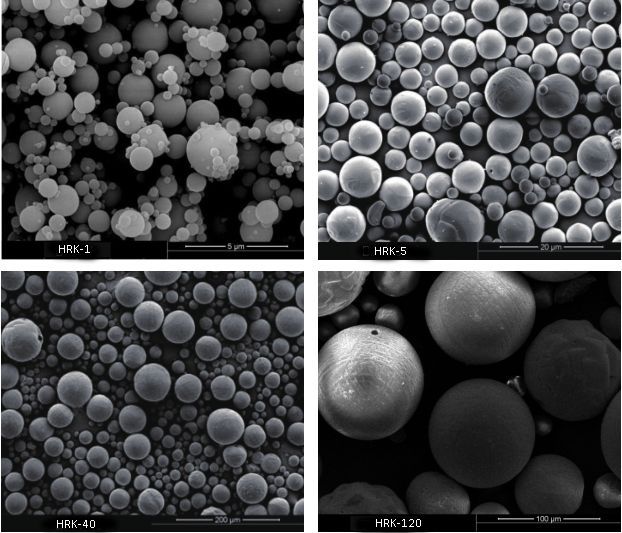

Electron micrograph

Khoom nta

High Filling: High degree ntawm spheroidization tus nqi, tswj particle loj tis, ua tau siab ceev filling rau silicone thiab epoxy resin, kom tau cov sib tov nrog tsawg viscosity thiab siab mus;

High Thermal Conductivity: Vim nws yuav luag zoo meej pob qauv, cov muab tub lim siv nyob rau hauv cov ntaub ntawv raw tuaj yeem ua tiav ntau txoj kev xa hluav taws xob.Tag nrho cov kev sib xyaw ua ke yog nyob rau hauv lub xeev zoo dispersion, yog li cov khoom kawg muaj thermal conductivity zoo heev thiab lub cev khoom;

Tsawg Abrasion: Piv nrog cov hmoov tsis sib xws, daim ntawv thov ntawm cov khoom siv kheej kheej tuaj yeem txo qhov kev puas tsuaj ntawm cov khoom sib tov, cov tshuab molding thiab lwm yam khoom siv, tom qab ntawd ua haujlwm ntev ntawm cov khoom siv.

Specification

| 技术指标 Yam khoom | 单位 Chav tsev | HRK 系列产品编号/HRK Series Product Code | ||||||||||

| HRK-1 | HRK-2 | HRK-5 | HRK-10 | HRK-20 | HRK-30 | HK-40 | TSI-70 | TSI-90 | TSI-120 | |||

| 粒度分布 Particle Loj | (D10) | µm | 0.71 ib | 0.69 ib | 2.54 ib | 4.55 ib | 10.5 | 16.88 Nws | 23.77 Nws | 44.32 Nws | 55.23 ib | 92.39 ib |

| (D50) | µm | 1.08 Nws | 2.18 | 5.52 ib | 10.43 Nws | 20.8 ib | 30.52 Nws | 41.54 ib | 71.54 ib | 87.96 ib | 122.98 Nws | |

| (D90) | µm | 3.21 | 5.24 ib | 9.09 ib | 20.8 ib | 37.24 Nws | 48.87 ib | 66.44 ib | 106.5 ib | 134.92 Nws | 172.07 Nws | |

| 比表面积 Qhov chaw tshwj xeeb | m2/g | 1.69 ib | 1.27 | 0.36 ib | 0.17 ib | 0.14 ib | 0.13 | 0.12 | 0.12 | 0.1 | 0.06 ib | |

| 电导率 Hluav taws xob conductivity | ua S/cm | 6.07 ib | 5.4 | 5.65 ib | 4.05 Nws | 6.87 ib | 7.95 ib | 4.65 ib | 6.18 | 8.15 Nws | 6.45 Nws | |

| Tus nqi PH | - | 7.53 ib | 7.79 ib | 7.7 | 7.9 ib | 7.62 ib | 7.7 | 7.8 ib | 7.7 | 7.9 ib | 7.54 ib | |

| 含水量 Moisture | % | 0.05 Nws | 0.03 ib | 0.03 ib | 0.03 ib | 0.03 ib | 0.03 ib | 0.03 ib | 0.03 ib | 0.03 ib | 0.04 ib | |

| 真密度 Muaj tseeb tiag | g/cm3 | 3.71 ib | 3.7 | 3.74 ib | 3.76 ib | 3.79 ib | 3.79 ib | 3.81 ib | 3.87 ib | 3.88 ib | 3.89 ib | |

| 球化率 Spheroidization Rate | % | 96 | 98 | 98 | 98 | 96 | 98 | 96 | 96 | 95 | 95 | |

| 化学成分 Tshuaj muaj pes tsawg leeg | Al2O3 | % | 99.87 ib | 99.94 ib | 99.89 ib | 99.94 ib | 99.92 ib | 99.93 ib | 99.94 ib | 99.92 ib | 99.94 ib | 99.92 ib |

| SiO 2 | ppm ua | 430 | 30 | 430 | 20 | 150 | 20 | 20 | 30 | 20 | 170 | |

| Fe2O 3 | ppm ua | 140 | 70 | 140 | 40 | 60 | 60 | 50 | 60 | 60 | 140 | |

| Na2O | ppm ua | 90 | 100 | 10 | 60 | 140 | 90 | 110 | 90 | 70 | 90 | |

Sem

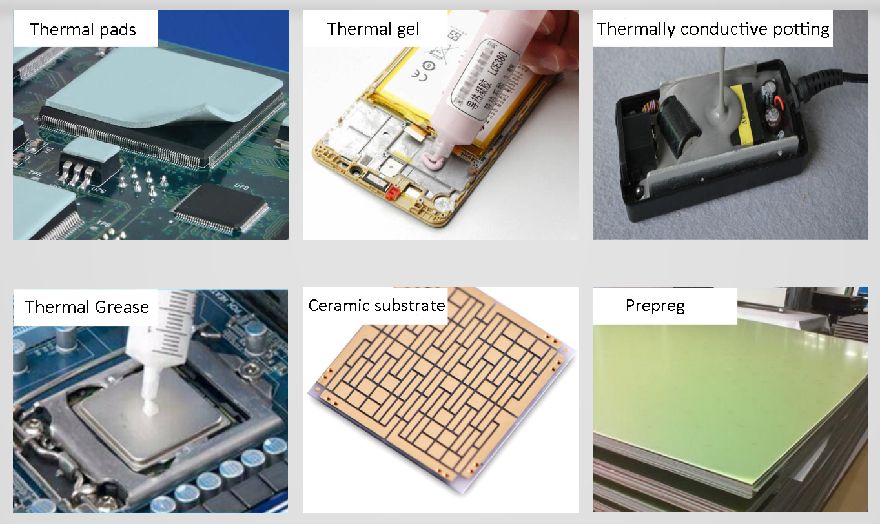

Daim ntawv thov

Thermal Interface Cov ntaub ntawv: thermal silica ncoo, thermal roj, thermally conductive potting kua nplaum, theem hloov cov ntaub ntawv

Thermally Conductive Engineering Plastics: LED teeb npog, hloov plhaub, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob kub dissipation;

Al-based Copper Clad Laminate: high-power LED Circuit Court substrate, fais fab Circuit Court boards, thiab lwm yam;

Alumina Ceramic Lim;

Thermal Spray Txheej.