IN625 Nickel Base Alloy Powder Inconel 625 Hmoov

Product Description

Huarui kub npib tsib xee-raws li alloy IN625 hmoov yog cov hmoov optimized, tshwj xeeb tshaj yog haum rau SLM txoj kev siv tshuab, xws li EOS Selective Laser Melting Equipment (EOSINT M Series), Lub tswv yim Laser Melting Equipment, Renishaw Laser Melting Equipment, American 3D Systems Laser Melting Equipment, thiab cov koom haum tshawb fawb hauv tsev thiab lub koom haum.

Los ntawm qhov sib txawv particle loj faib, nws tseem tuaj yeem muab faib ua cov tshuaj molding hmoov, laser cladding hmoov, txau hmoov, kub isostatic nias hmoov thiab lwm yam.

Specification

| Tshuaj muaj pes tsawg leeg (%) ntawm Inconel 625 Powder | ||||||

| Cr | Co | Al | Mo | Mn | Ti | Nb |

| 20-23 | ≤1.0 | ≤0.4 | 8.0-10.0 Nws | ≤0.5 | ≤0.4 | 3.15-4.15 dr hab |

| Fe | C | Si | P | S | O | Ni |

| ≤0.5 | ≤0.1 | ≤0.5 | ≤ 0.015 | ≤ 0.15 | ≤ 0.02 | Bal |

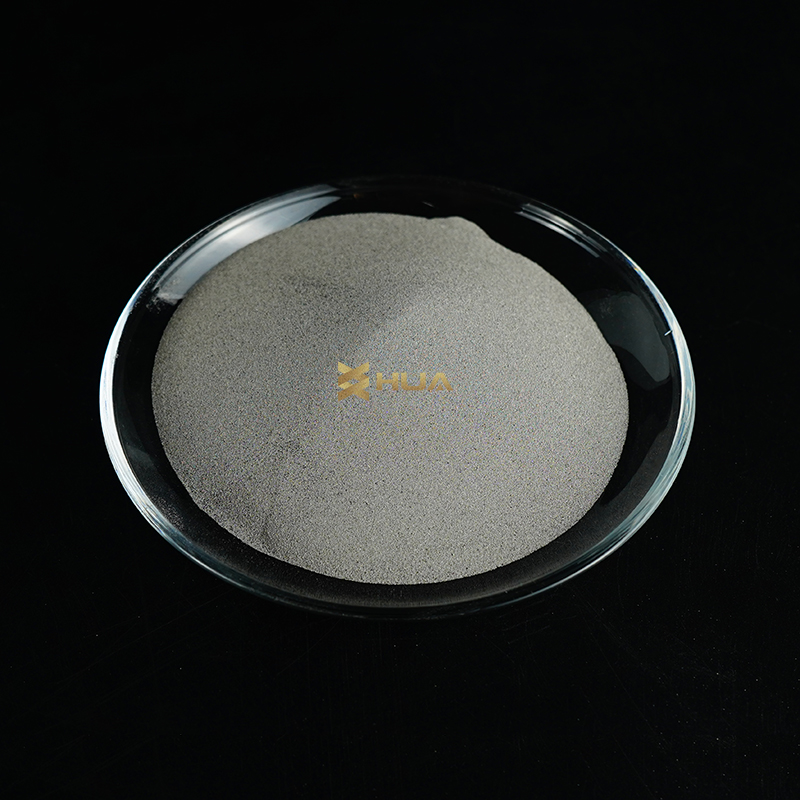

| Pom tseeb ntom: 4.50g / cm3 | Xim: grey | Puab: spherical | ||||

| Particle Loj | 15-53 micron;45-105 micron;45-150 micron | |||||

| Inconel 625 Powder Properties | ||||||

| Qhov Loj | 0 ~ 25 hli | 0 ~ 45 hli | 15 ~ 45 hnub | 45-105 hli | 75-180 Nws | |

| Morphology | kheej kheej | kheej kheej | kheej kheej | kheej kheej | kheej kheej | |

| Particle Loj Distribution | d10:6 ua | d10:9 ua | d10:14 ua | d10:53 ua | 10:78 ua | |

| d50:16 ua | d50:28 ua | d50:35 ua | 50:69 ua | d50:120 ua | ||

| d90:23 ua | 90:39 ua | 90:45 ua | d90:95 ua | 90:165 ua | ||

| Flow peev | N/A | ≤30S | ≤ 28S | ≤16S | ≤18S | |

| Pom Ntsig | 4.2g / cm3 | 4.5g / cm3 | 4.4g / cm3 | 4.5g / cm3 | 4.4g / cm3 | |

| Cov ntsiab lus oxygen (wt%) | O: 0.06 ~ 0.018wt%, ASTM tus qauv: ≤0.02 wt% | |||||

| 3D luam ntawv Gas Atomized Inconel 625 Hmoov nrog tus nqi zoo tshaj | ||||||

| (tsis tshua muaj oxygen, siab sphericity thiab fluidity zoo) | ||||||

Daim ntawv thov

1. HVOF

2. Plasma txheej

3. 3D luam ntawv / additive manufacturing

4. hmoov vuam

5. hlau txhaj tshuaj molding

6. kub isostatic

Yam khoom

Peb kuj muab Inconel 718 hmoov, NiCr hmoov, NiAl hmoov, Ni20-Ni65 hmoov, txais tos nug!