Additive Manufacturing Stainless hlau hmoov 316l hmoov rau 3d Printing

Product Description

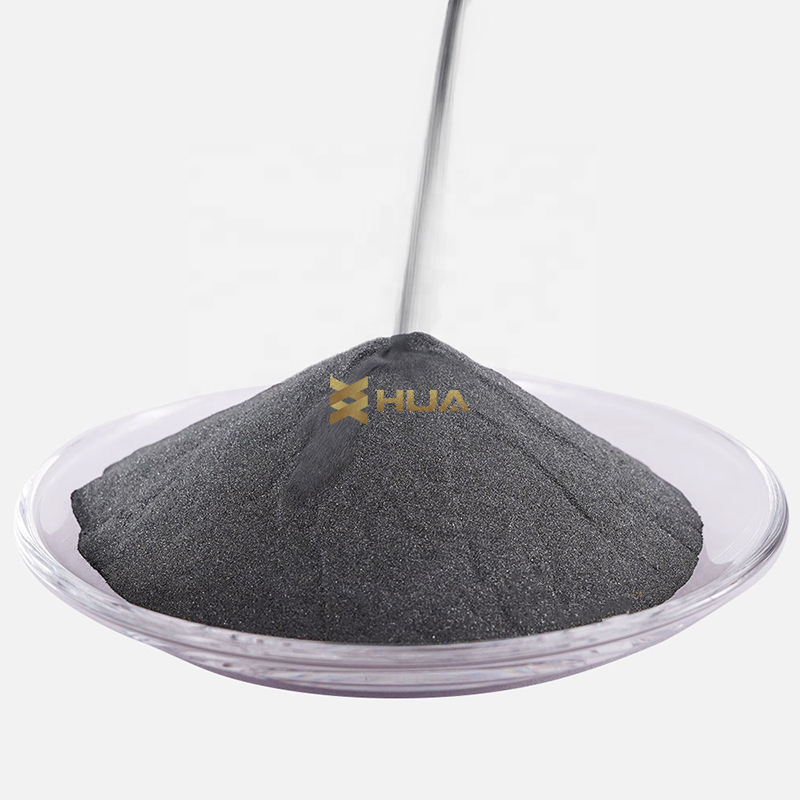

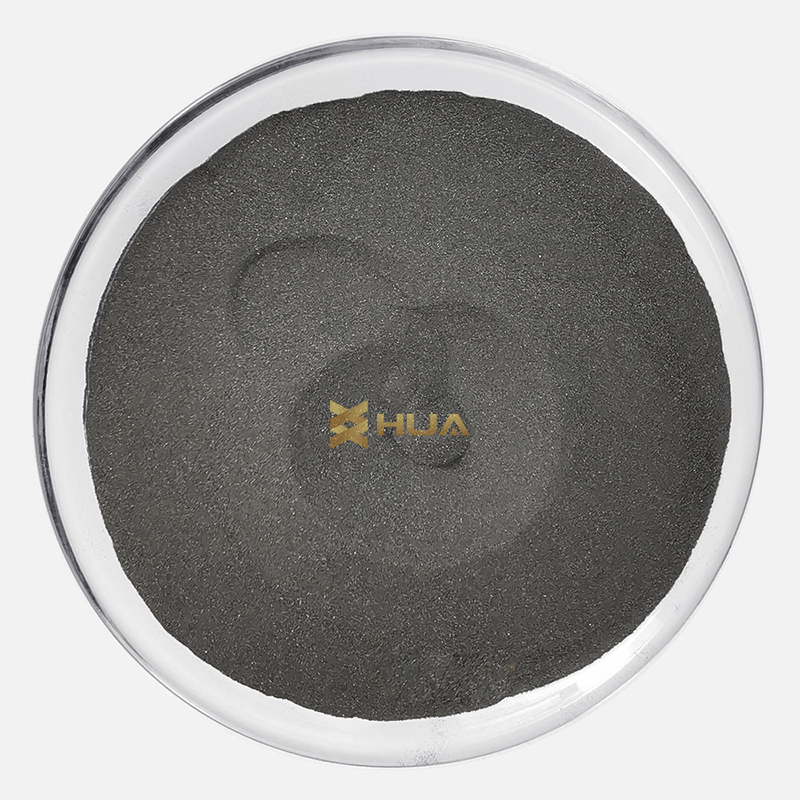

Stainless hlau hmoov yog tsim los ntawm cov txheej txheem dej atomization thiab muaj corrosion kuj zoo thiab kav ntev.Stainless hlau hmoov muaj ntau yam kev lag luam siv.

Muab ntau yam stainless hlau hlau hmoov nrog sib txawv particle loj.

Raws li kev siv

1. Kub Isostatic Nias

2. Hlau Txhaj Moulding

3.3D luam ntawv

4.Thermal txau

Raws li cov txheej txheem ntau lawm

1. Dej atomization

2. Dej gas ua ke atomization

3. Gas atomization

4.Nqus atomization

Cov lus qhia tshwj xeeb

| Stainess steel hmoov muaj pes tsawg leeg% | |||||||||

| Qib | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8–13 |

|

|

| 0.15-0.3 Nws | ≤0.2 | ≤ 0.15 | ≤1 |

| 304 | 18-20 | 8–12 |

|

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.08 | ≤1 |

| 303l ua | 17-19 | 8–13 |

|

|

| 0.15-0.3 Nws | ≤0.2 | ≤ 0.03 | ≤1 |

| 304l ua | 18-20 | 8–12 |

|

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.03 | ≤1 |

| 316l ua | 16-18 | 10-14 |

|

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.03 | ≤1 |

| 317l ua | 18-21 | 12-16 | 3-4 |

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤ 0.03 | ≤ 0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.08 | ≤1 |

| 303 TSI | 17-19 | 8–13 |

|

| 2 | 0.15-0.3 Nws | ≤0.2 | ≤ 0.03 | ≤1 |

| 304 TSI | 17-19 | 8–13 |

|

| 2 | ≤ 0.03 | ≤ 0.04 | ≤ 0.03 | ≤1 |

| 316 TSI | 16-19 | 10-14 | 2-3 |

| 2 | ≤ 0.03 | ≤ 0.04 | ≤ 0.03 | ≤1 |

| 410l ua | 11.5-13.5 Nws |

|

|

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.03 | ≤1 |

| 430l ua | 16-18 |

|

|

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.03 | ≤1 |

| 434l ua | 16-18 |

| 0.75-1.25 Nws |

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.08 | ≤1 |

| 434 LWB | 16-18 |

| 0.75-1.25 Nws | 0.4-0.6 hli |

| ≤ 0.03 | ≤ 0.04 | ≤ 0.03 | ≤1 |

| 410 | 11.5-13.5 Nws |

|

|

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤ 0.03 | ≤ 0.04 | 0.25/0.35 Nws | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.08 | ≤1 |

| 434 ib | 16-18 |

| 0.75-1.25 Nws |

|

| ≤ 0.03 | ≤ 0.04 | ≤ 0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤ 0.03 | ≤ 0.04 | 0.9/1.2 | ≤1 |

| 17-4 PAB | 15-17.5 Nws | 3-5 |

| 0.15-0.456 Nws | 3-5 | ≤ 0.03 | ≤ 0.04 | ≤ 0.07 | ≤1 |

| 15-5 PHN | 14-15.5 Nws | 3.5-5.5 |

|

| 2.5-4.5 | ≤ 0.03 | ≤ 0.04 | <=0.07 | ≤1 |

Daim ntawv thov

Stainless hlau hmoov yuav siv tau rau thermal spraying, hmoov metallurgy, hmoov metallurgy xovxwm sintering (PM), txhaj tshuaj molding (MIM) sintering lim, thiab lwm yam., dej atomization oxygen cov ntsiab lus<4000PPM, roj atomization<1000PPM.

Qhov zoo ntawm HUARUI stainless hlau hmoov

●Txawm cov hmoov muaj pes tsawg leeg, tsawg impurities

● Siab sphericity

● Cov pa oxygen tsawg

● Zoo flowability

● High loose density, high kais density

● Tsawg hollow hmoov, tsawg satellite hmoov

Kev tswj hwm qhov system

1.Huarui muaj kev tswj xyuas zoo.Peb sim peb cov khoom ua ntej tom qab peb ua tiav peb cov khoom, thiab peb sim dua ua ntej txhua qhov khoom xa tuaj, txawm tias cov qauv.Thiab yog tias koj xav tau, peb xav lees txais cov neeg thib peb los kuaj.Tau kawg yog tias koj nyiam, peb tuaj yeem muab cov qauv rau koj los kuaj.

2.Our khoom zoo yog guaranteed los ntawm Sichuan Metallurgical lub koom haum thiab Guangzhou lub koom haum ntawm hlau tshawb fawb.Kev koom tes ntev nrog lawv tuaj yeem txuag tau ntau lub sijhawm sim rau cov neeg siv khoom.